PYROLYT (16-140kW)- Wood/ briquette gasification boiler

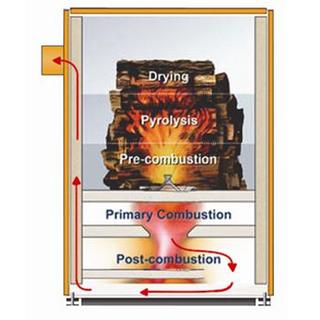

The PYROLYT boiler is the most modern form of wood boiler. The wood is placed in the upper chamber of the boiler, where the dehumidification and preheating process takes place. The combustion is carried out downwards using the reverse flame method during which the wood is gasified. Special refractory plates take the thermal load, which is up to 1200οC.

With the pyrolysis method we achieve very high efficiencies (up to 92%), resulting in fuel savings of 25-30% compared to a conventional wood boiler. In addition, we have a much smaller amount of ash. When feeding wood fuel we open the by-pass damper by moving the lever to ensure the boiler traction.

All PYROLYT boilers are equipped with an integrated cooling serpentine for protection against overheating.

- Modern design.

- High performance.

- Solid construction.

- Long life span.

- Saving money.

- Suitable only for dry wood (humidity <20%).

- Autonomy 8-12 hours.

- Large combustion chamber.

- Ceramic refractory flame spreading materials.

- Stand-by operation.

- Version with traction fan for difficult chimneys.

- Simple use. Easy maintenance.

- Minimum amount of ash.

- Environmentally friendly, no CO emissions to the environment.

- Ideal solution for heating without oil or gas.

Ventilator

Refractory ceramic firebox hearth

Overheating protection serpentine

| ΤΥΠΟΣ/TYPE | ΙΣΧΥΣ/ POWER | |

| kcal/h | kW | |

| PYROLYT 16 | 14.000 | 16 |

| PYROLYT 23 | 20.000 | 23 |

| PYROLYT 35 | 30.000 | 35 |

| PYROLYT 47 | 40.000 | 47 |

| PYROLYT 58 | 50.000 | 58 |

| PYROLYT 69 | 60.000 | 69 |

| PYROLYT 81 | 70.000 | 81 |

| PYROLYT 93 | 80.000 | 93 |

| PYROLYT 116 | 100.000 | 116 |